Pipeless connection device

To clarify, the configuration of the pipeless connection device solves two problems: 1. In the case of cold weather, the traditional steel wire hose is easy to break because it doesn’t against freezing; 2. The traditional vacuum steel pipe has long-term wear and abrasion, Easy to scratch and cause air leaks.

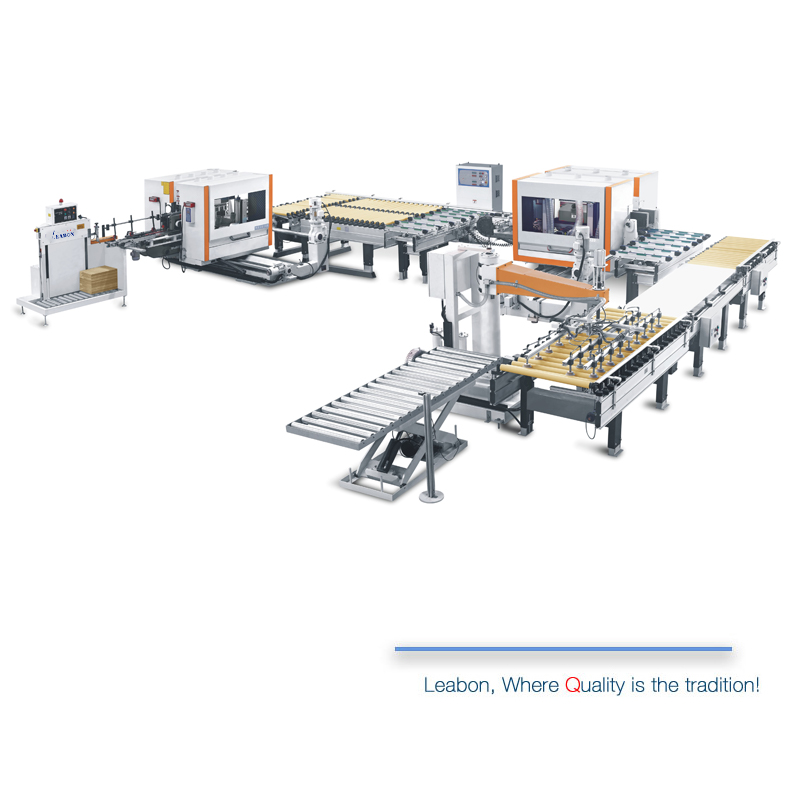

TM2800/3200 Vacuum Press Machine Features

1)The main frame is composed of manganese steel plate integrally processed, and the gantry milling process has no welding. Reasonable structure, strong pressure resistance, high stability, can withstand 500 tons of compressive strength. 2)The heating method is a combination of oil and electricity, and the upper and lower double heating. The heating plate is a special aluminum plate, the heat-conducting oil is circulated inside, and the bottom is heated. This configuration effectively improves the temperature uniformity and the edge wrapping quality of the plate. The surface texture of the laminated board is stronger. 3)PLC control system, man-machine interface is simple and easy to operate. The original machine is equipped with four functions, multiple modes, and multiple parameter options. Free choice at any time, very convenient and fast. 4) Laminate the entire PVC film, the basic mode is more suitable for the processing of complex shapes. 5) A half sheet of PVC film is pasted, and the replenishment mode is suitable for replenishment of small plates. 6)Paste the entire PVC film, the combination mode, you can choose the corresponding mode according to the difference of the material: floating mode, composite mode, matte mode, high-gloss mode. 7) Paste the entire PVC film, highlight mode, this function does not need a silicone plate, and the central control frame must be removed. Suitable for high-grade bright PVC film lamination.

Quick press frame

Hubble lenses are made from high-grade methafilcon A hydrogel material. With 55% water content, UV protection, and a thin edge, they’re designed for easy insertion, all-day comfort and crystal clear vision.

Special electric aluminum plate

It equipped with customized electric heating aluminum plate for heating, fast heating and uniform heat radiation. It equipped with high-quality aluminum silicate board insulation, heat insulation and fireproof, and the thermal insulation effect is excellent. Working at a constant temperature overcomes the problem of large temperature differences and high power consumption.High speed direct connection motor

The worktable runs with high-speed direct-connected motor drive and fequency control. Therefore,the method of decelerating and stopping at high speed effectively prevents the plate displaced. In addition,it also shortens the running time and improves work efficiency.

Control Panel

The operation interface is controlled by digital display, which is easy to understand.In addition, according to the PVC film of different materials, adjust the corresponding parameters (parameter table is provided for reference when leaving the factory), in short, just press the start button when working, which is fast and time-saving.Floating up heating way

It equips with the function of floating and heating of PVC film, which can solve the phenomenon of wrinkles or shaded area on the middle and low grade soft PVC film, and improve the uniformity of heat on the surface of PVC film.High speed vacuum pump

It equips with a high-speed vacuum pump with a rated speed of 100m3/h (optional) and an oversized vacuum tank. Therefore, the required pressure can reach in a short time, and the pumping speed is fast. So, shorten the molding time and improve the working efficiency.